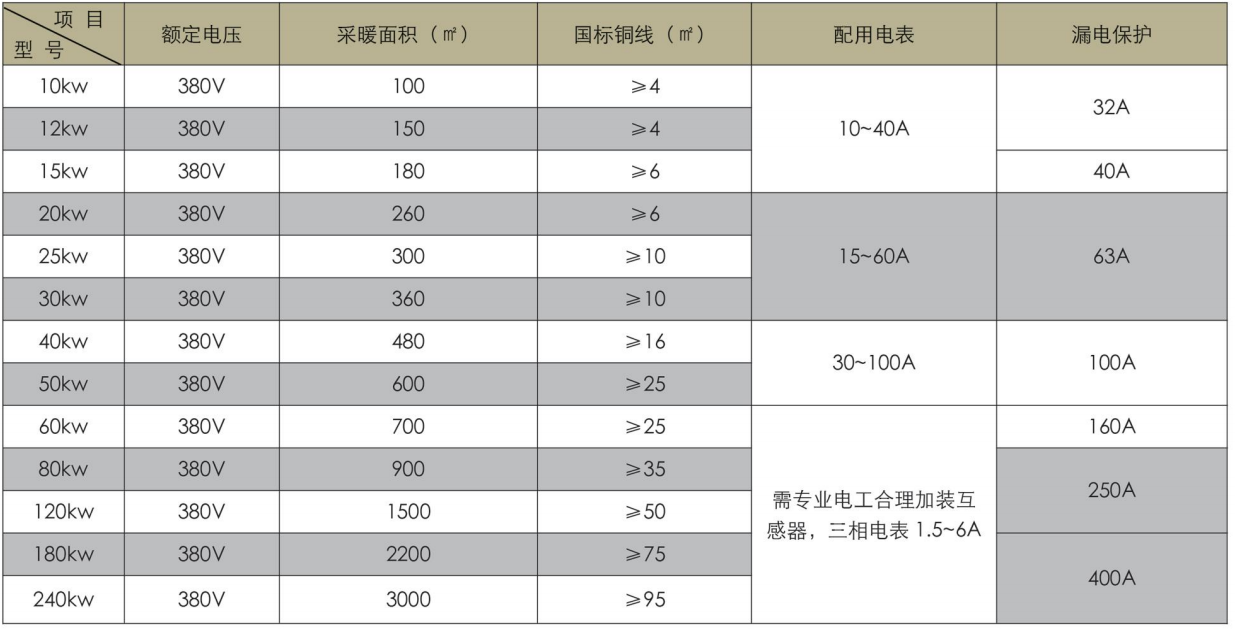

电磁采暖炉

| 厂家: | 青州市正和温控设备有限公司 |

|---|---|

| 联系人: | 张经理 |

| 电话: | 13562600826 |

| 邮箱: | zhenghe481@126.com |

| 地址: | 山东 ·青州 ·黄楼街道大尹 |

| 留言咨询 更多信息 | |

| 分享: |

|

电磁感应加热原理,利用交流电整流成直流电再逆变为高频交变电流,作用在电感线圈上从而产生交变磁场,使炉体产生无数小涡流,通过涡流碰撞进行加热炉体,使炉体内的水达到加热的目的,水与线圈之间有大于20MM的绝缘隔热材料,热效率可达97%,安全预热时间短,升温速度快。电磁采暖炉系统由加热控制器、智能操作系统、电磁线圈、加热炉体及保护电路等组成。

Based on the principle of electromagnetic induction heating, the alternating current is rectified into a direct current and then reversed into a high frequency alternating current, which acts on the inductance coil to produce an alternating magnetic field and causes numerous small eddy currents to be generated in the furnace body. The furnace body is heated by Eddy current collision, the water in the furnace body can be heated. There is insulation material larger than 20MM between the water and the coil, the thermal efficiency can reach 97% , the safe preheating time is short, and the temperature rising speed is fast. The electromagnetic heating furnace system is composed of heating controller, intelligent operating system, electromagnetic coil, heating furnace body and protection circuit.

。